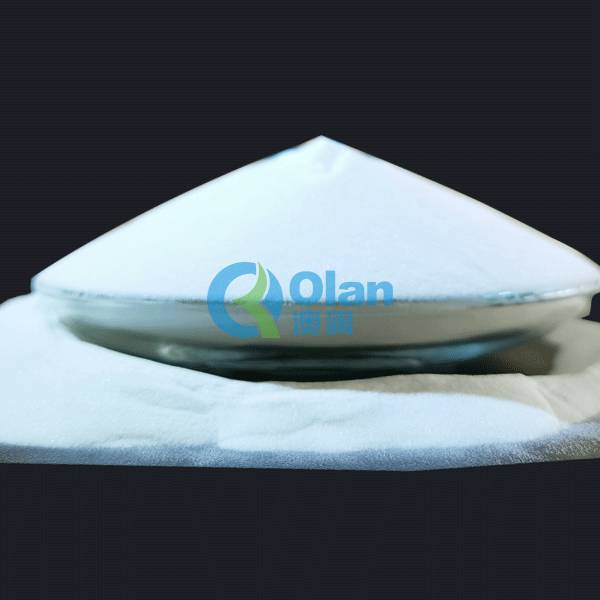

Sandblast iav hlaws 280 #

Khoom Muaj nuj nqi

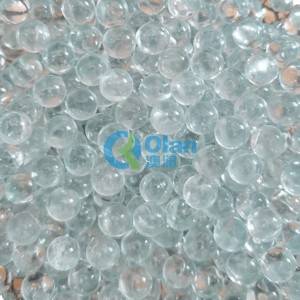

Blasting nrog Iav Beads nyob rau hauv siab yuav tswj cov khoom tsis muaj qhov hloov pauv, tsis muaj paug thiab tsis hnav dhau. Nws ua cov xim hlau huv si zoo ib yam. Cov Khoom Hluav Taws Xob Hluav Taws Xob xws li Aluminium Oxide, Xuab Zeb, Cov Khaub Ncaws Hlau yuav cia ib qho tawm ntawm Zaj Duab Zaj Hluav Taws Xob rau ntawm qhov chaw lossis los txiav kev txiav txim. Iav hlaws feem ntau me dua thiab sib dua li lwm cov xov xwm thiab tuaj yeem siv rau peen rau hauv cov xov hluav taws xob kom zoo ntawm cov xov thiab qhov chaw mos uas qhov muaj zog tsawg heev yuav tsum muaj. Blasting Blasting nrog lub iav hlaws ua tiav npaj cov hlau saum npoo rau txhua yam ntawm cov xim ntawm nws xws li tha xim, plating enameling lossis iav txheej. Cov txiaj ntsig ntxiv ntawm iav hlaws blasting xws li hais tias koj tuaj yeem siv lawv rau ob peb lub voj voog ua ntej lawv tsis ua lub ntsej muag huv si. Nws yog ib txwm muaj rau iav hlaws xov xwm mus rau 4 - 6 lub voj voog ua ntej qhov xav tau hloov. Thaum kawg, cov iav hlaws tuaj yeem siv tau rau hauv qhov nqus los yog lub siab tawg tshuab. Qhov no ua rau nws muaj peev xwm ua ntau yam thiab tuaj yeem pab muab lub moj tej tawg sib txuas lus xov xwm uas ua rau koj lub txee rau txo qis.

Khoom Muag Khoom

Cov khoom tseem ceeb tshwj xeeb rau kev ntsuas phom raws li cov lus hauv qab no:

| Tsis yog. | Txoj kab uas hla (um) | Sib nug sieve loj |

| 1 | 850-425 | 20-40 |

| 2 | 425-250 | 40-60 |

| 3 | 250-150 | 60-100 |

| 4 | 150-105 | 100-140 |

| 5 | 105-75 | 140-200 |

| 6 | 75-45 | 200-325 |

Koj tuaj yeem xaiv qhov sib txawv me me iav hlaws ntawm 45um-850um raws li kev ua haujlwm sib txawv.

Lub Zog Loj Cov iav hlaws (rau Blasting)

Nrog rau kev sib xyaw ua kom muaj huab cua ua hluav taws xob tsis zoo, cov khoom no yog tsim los ntawm txau cov hlaws dai hauv qab kev kub ceev thiab nias siab rau ntawm qhov chaw ua haujlwm rau kev sib tsoo thiab polishing.

Lwm lub hom phiaj ntawm cov khoom yog raws li hauv qab no:

1. Ua kom pom cov pwm sib txawv ntawm kev cuam tshuam forging, forging, iav, roj hmab thiab yas, hlau nrum thiab extrusion.

2. Tshem tawm tensile ntxhov siab, ua kom lub neej qaug zog thiab txhim kho kev nyuaj siab corrosion. Piv txwv li, dav hlau lub tshuab ua haujlwm turbo, dav hlau, ncej, tsav tsheb hauv qab, ua haujlwm sib txawv thiab cov iav, thiab lwm yam.

3. Ntxuav thiab tshem tawm qeeb thiab ntug tawg rau ntawm cov ntawv cog lus thiab lub hnab yas sib khi lub log ua ntej stannum soldering

4. Tshem cov cag tawm hauv lub piston thiab lub tog raj kheej thiab muab qhov ci ci thiab ib nrab ntawm qhov tsis zoo rau cov cuab yeej kho mob thiab cov khoom siv hauv lub tsheb

5. Ntsuas cov tshuab hluav taws xob thiab cov khoom siv xws li lub voj, hluav taws xob txhuam thiab rotor ntawm thaum kho hnyav

6. Ntxuav thiab tshem tawm cov burr ntawm cov raj hlau thiab meej-melten tsis-ferrous hlau raj. Siv rau peening aggrandizement thiab polishing ntawm textile machinery yam.

Lub Zog Loj Cov iav hlaws rau txhawm rau tawg

| Hom | Ntxaij | Nthuav Loj μ m |

| 30 # | 20-40 | 850-425 |

| 40 # | 30-40 | 600-425 |

| 60 # | 40-60 | 425-300 |

| 80 #. | 60-100 | 300-150 |

| 100 # 100 | 70-140 | 212-106 |

| 120 #. | 100-140 | 150-106 |

| 150 #. | 100-200 | 150-75 |

| 180 #. | 140-200 | 106-75 |

| 220 #. | 140-270 | 106-53 |

| 280 # | 200-325 | 75-45 |

Daim ntawv pov thawj

Ntim

Raws li cov neeg yuav tsum tau muaj.