Sandblast iav hlaws 80 #

Khoom Muaj nuj nqi

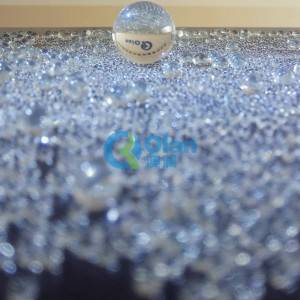

Sandblasting iav hlaws nrog cov yam ntxwv ntawm qee yam tshuab ua kom tawv, lub zog thiab lub zog ruaj khov tshuaj. Lawv tsim tawm los ntawm cov dej qab zib kua txiv qaub silica iav thiab tuaj yeem siv cov khoom tua blasting tshem tawm ntau ntau yam ntawm qhov tsis zoo saum npoo av, nrog rau cov hlau ua kom huv, ua tiav saum npoo, peening, deburring. Nws txo qis dua qhov pom ntawm txhua qhov kev puas tsuaj, khawb, me qhov tsis xws luag tom qab vuam, sib tsoo, lossis chaw vuam thiab tsa cov khoom lag luam corrosion thiab pab txhim kho kev hnav lub peev xwm.

Iav hlaws blasting yog tsim nyog tsis tsuas yog rau kev kho zaum kawg ntawm ib yam khoom tshiab lossis los ua kev kho mob ua ntej tom qab cov txheej txheem tshuaj lom neeg (electroforming, anodic oxidation), nws kuj tseem ua pa lub neej tshiab rau hauv cov khoom qub, puas yog nws lub cev muaj zog, kos duab thiab cov khoom zoo nkauj lossis khoom siv sab hauv.

Khoom Muag Khoom

Cov khoom tseem ceeb tshwj xeeb rau kev ntsuas phom raws li cov lus hauv qab no:

| Tsis yog. | Txoj kab uas hla (um) | Sib nug sieve loj |

| 1 | 850-425 | 20-40 |

| 2 | 425-250 | 40-60 |

| 3 | 250-150 | 60-100 |

| 4 | 150-105 | 100-140 |

| 5 | 105-75 | 140-200 |

| 6 | 75-45 | 200-325 |

Koj tuaj yeem xaiv qhov sib txawv me me iav hlaws ntawm 45um-850um raws li kev ua haujlwm sib txawv.

Lub Zog Loj Cov iav hlaws (rau Blasting)

Nrog rau kev sib xyaw ua kom muaj huab cua ua hluav taws xob tsis zoo, cov khoom no yog tsim los ntawm txau cov hlaws dai hauv qab kev kub ceev thiab nias siab rau ntawm qhov chaw ua haujlwm rau kev sib tsoo thiab polishing.

Lwm lub hom phiaj ntawm cov khoom yog raws li hauv qab no:

1. Ua kom pom cov pwm sib txawv ntawm kev cuam tshuam forging, forging, iav, roj hmab thiab yas, hlau nrum thiab extrusion.

2. Tshem tawm tensile ntxhov siab, ua kom lub neej qaug zog thiab txhim kho kev nyuaj siab corrosion. Piv txwv li, dav hlau lub tshuab ua haujlwm turbo, dav hlau, ncej, tsav tsheb hauv qab, ua haujlwm sib txawv thiab cov iav, thiab lwm yam.

3. Ntxuav thiab tshem tawm qeeb thiab ntug tawg rau ntawm cov ntawv cog lus thiab lub hnab yas sib khi lub log ua ntej stannum soldering

4. Tshem cov cag tawm hauv lub piston thiab lub tog raj kheej thiab muab qhov ci ci thiab ib nrab ntawm qhov tsis zoo rau cov cuab yeej kho mob thiab cov khoom siv hauv lub tsheb

5. Ntsuas cov tshuab hluav taws xob thiab cov khoom siv xws li lub voj, hluav taws xob txhuam thiab rotor ntawm thaum kho hnyav

6. Ntxuav thiab tshem tawm cov burr ntawm cov raj hlau thiab meej-melten tsis-ferrous hlau raj. Siv rau peening aggrandizement thiab polishing ntawm textile machinery yam.

Lub Zog Loj Cov iav hlaws rau txhawm rau tawg

| Hom | Ntxaij | Nthuav Loj μ m |

| 30 # | 20-40 | 850-425 |

| 40 # | 30-40 | 600-425 |

| 60 # | 40-60 | 425-300 |

| 80 #. | 60-100 | 300-150 |

| 100 # 100 | 70-140 | 212-106 |

| 120 #. | 100-140 | 150-106 |

| 150 #. | 100-200 | 150-75 |

| 180 #. | 140-200 | 106-75 |

| 220 #. | 140-270 | 106-53 |

| 280 # | 200-325 | 75-45 |

Cov Lus Qhia Txog Txuj Ci

Zog: Huv thiab pob tshab, tsis pom npuas thiab impurity.

Qhov ceev:2.4-2.6g / cm3

Hardness:6-7 (Moh's)

Hlaws kheej kheej:75%

SiO2 cov ntsiab lus:> 72%

Daim ntawv pov thawj

Ntim

Raws li cov neeg yuav tsum tau muaj.